MUD BRICK STUDY

Why Mudbrick?

In an age of rising digital technologies, we have found ourselves pushing towards new forms, material and process. We believe we must revisit materials and methods dating back way before the Industrial Revolution.

A time when the craft and precision was a handmade artform. Digital technologies, like mold-making and robotic 3d printing allow us to regain the aspect of precision and repeatability but material responsibility is still in our hands; it is to study, learn, and expand upon the past to create a more informed future of making.

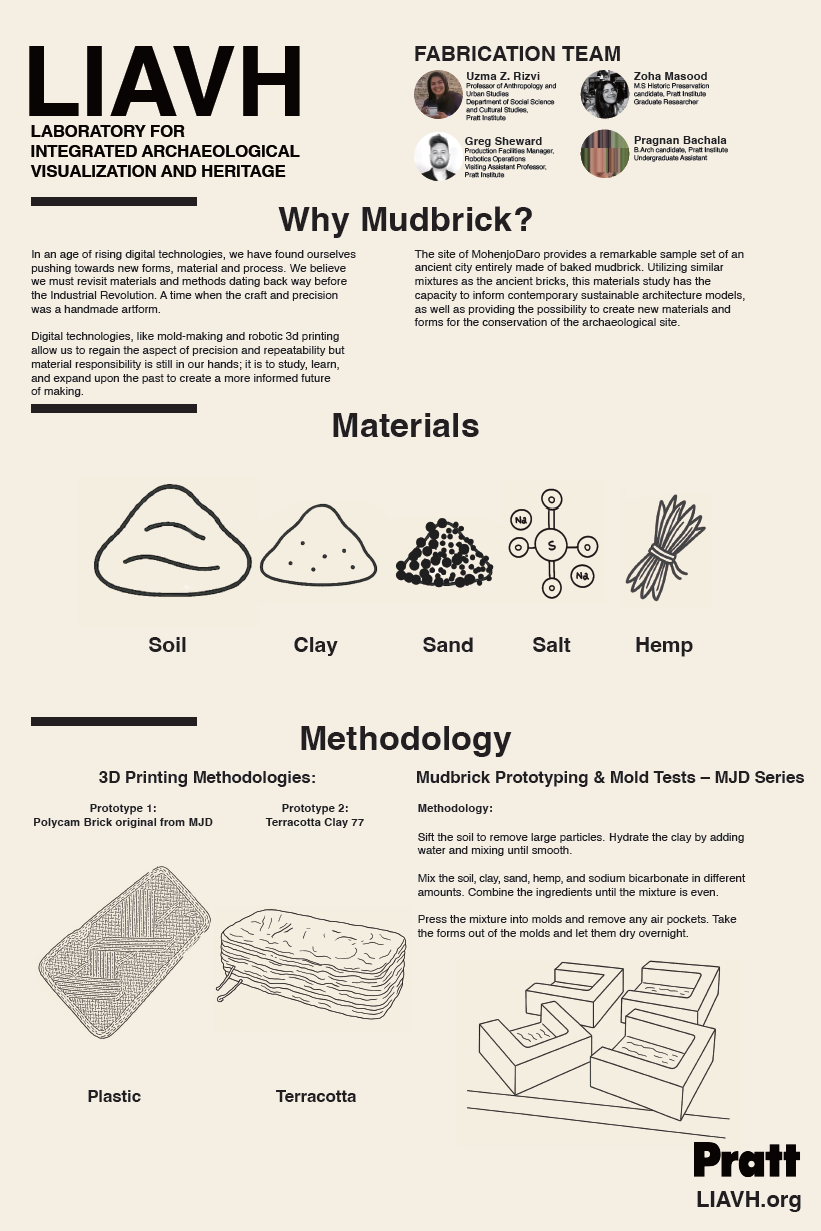

3d Printing Methodologies

Prototype 1: PLA 3D print of a well brick from MohenjoDaro

Prototype 2: Terracotta Clay 77 3D print of a well brick from MohenjoDaro

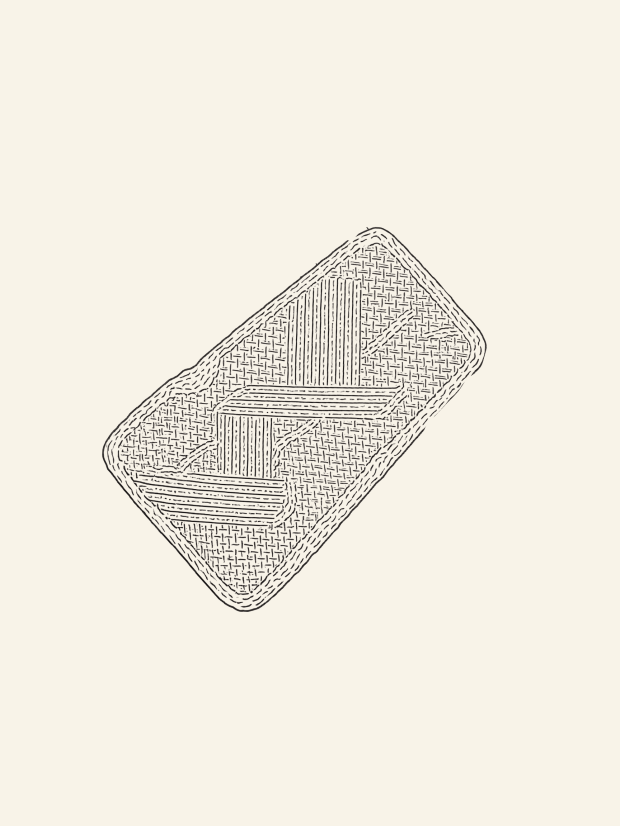

Mudbrick Prototyping & Mold Tests – MJD Series

Methodology:

Sift the soil to remove large particles. Hydrate the clay by adding water and mixing until smooth. Mix the soil, clay, sand, hemp, and sodium bicarbonate in different amounts. Combine the ingredients until the mixture is even. Press the mixture into molds and remove any air pockets. Take the forms out of the molds and let them dry overnight.

Initial test prints for the mudbrick failed due to issues with the machinery and mix. We decided to pivot to molded bricks for the exhibition. Four mold pieces were printed (two top, two bottom) based on our mudbrick dimensions. Using the same clay mixtures with some added water, we began testing mold-based fabrication.

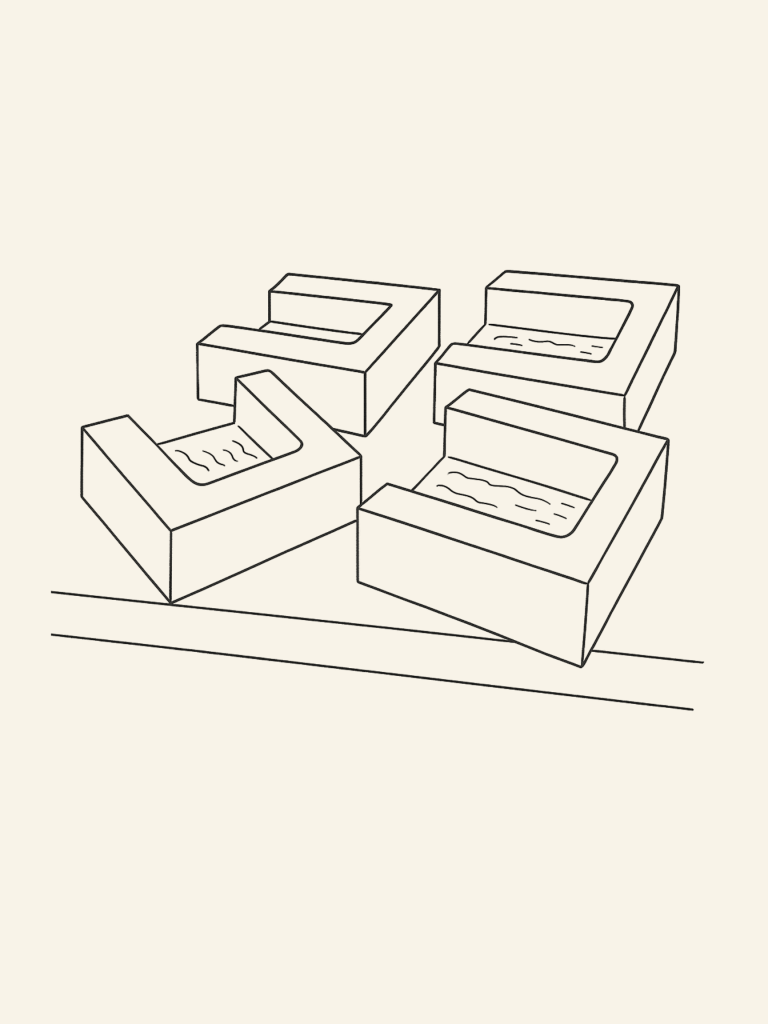

Top row: 3D printing in process and making mudbrick mixtures Bottom row: Greg Sheward (Left); Mudbrick study display at ‘Visualizing Care’ exhibition (Right)